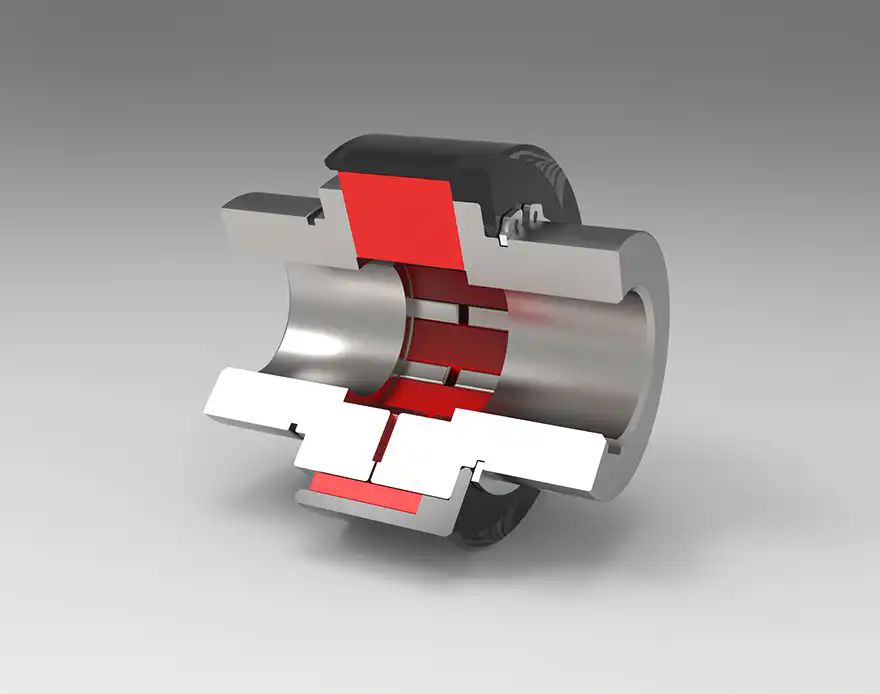

Internal view of a Quick Flex coupling from R+L Hydraulics with easy-to-replace elastomer element. Photo: R+L Hydraulics R+L Hydraulics

Internal view of a Quick Flex coupling from R+L Hydraulics with easy-to-replace elastomer element. Photo: R+L Hydraulics R+L Hydraulics now offers its Quick Flex elastomeric couplings in new configurations for tough environments. Manufactured by R+L Hydraulics in Germany, the Quick Flex elastomeric couplings series from Lovejoy can be equipped with optional seals to keep out dirt and dust in contaminated or outdoor settings. Other variants include UltraTemp designs for continuous temperatures up to 177°C and compact versions with shortened hubs for tight installation spaces.

Every version of the Quick Flex series delivers the same core benefit: low maintenance, fast elastomer changes, and no need for lubrication. This makes them ideal for applications where uptime is critical. Quick Flex couplings are used in power transmission systems to protect surrounding components such as rolling bearings and to dampen vibration and shock loads. They are proven in demanding operations including steel and metal plants, kilns, crushers, mills, sawmills, and more.

Unlike conventional designs, Quick Flex couplings require no oil or grease, which supports sustainability goals and reduces service complexity. Detlef Peick, business development manager at R+L Hydraulics, said: “Checking the elastomer takes just minutes. If it needs replacing, it is a quick swap. Even if you delay replacement and the insert fails, the coupling protects itself — the hubs stay intact thanks to the non-contact design. That keeps downtime and costs low.”

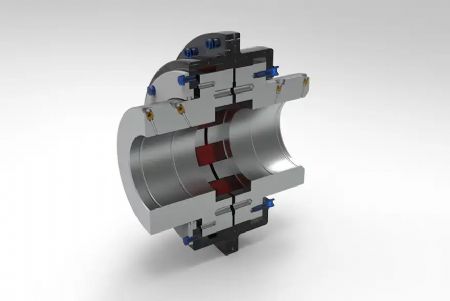

Pictured right: internal view of a Quick Flex coupling from R+L Hydraulics with seal

Pictured right: internal view of a Quick Flex coupling from R+L Hydraulics with sealBecause the coupling avoids metal-to-metal contact, hub wear is minimal. The elastomer insert is the only spare part needed. Mr Peick noted: “That is a big cost advantage. Once installed, you only replace the insert — not entire components — which makes a real difference over time.”

Quick Flex couplings are modular and available in multiple designs, sizes, and configurations. Engineers can mix and match housings, hubs, and elastomers — including versions with single or double flexible extensions — to fit their application; and if a standard combination does not meet requirements, R+L Hydraulics offers custom configurations, including options to integrate sensors, brake discs, or emergency drives.

Elastomer inserts are available in three hardness levels, with temperature resistance up to 177°C, and are built to absorb misalignment and transmit high torques reliably. The Quick Flex range covers torque ratings from 43 to 902.5kNm (continuous), up to 1,800kNm (peak). The couplings are available with bore sizes from 10 to 500mm and with spacer options for shaft separations up to 3,000mm. Bore types include metric, imperial, keyed, tapered, and splined.

In addition to couplings, R+L Hydraulics designs and manufactures hydraulic and power transmission components, including torsional and jaw couplings, bellhousings, damping elements, heat exchangers, coolers, and hydraulic tanks. These products serve a wide range of applications in mechanical engineering, marine and vehicle systems, steelmaking, offshore platforms, and custom plant construction.