Germany-based

Plasmatreat GmbH will unveil a pioneering solution for industrial surface cleaning at the

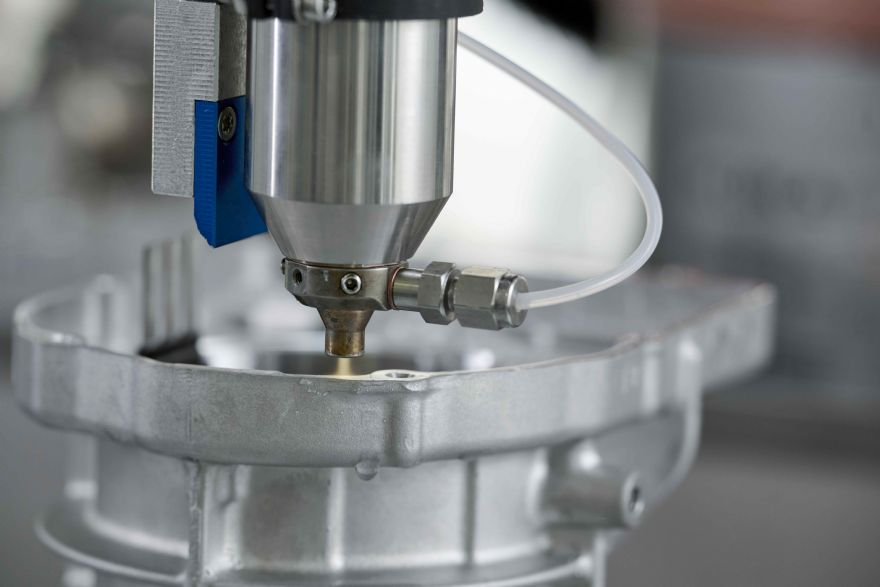

parts2clean trade show taking place in Stuttgart, 7-9 October 2025 (Booth D52, Hall 10). Called HydroPlasma, ths new solution can remove both stubborn organic and inorganic residues and will be demonstrated live on the stand with a Plasma Treatment Unit (PTU).

HydroPlasma — a combination of the company’s patented Openair-Plasma and distilled water — enables the efficient, environmentally-friendly, and material-friendly preparation of substrates for demanding processes such as structural bonding, sealing, or coating.

In many manufacturing processes, such as those in the automotive industry and renewable energy sector, achieving absolute surface cleanliness is crucial for ensuring high-quality and long-lasting results. Residues that can negatively affect subsequent processes, such as fingerprints or oil residues, have to be reliably removed. HydroPlasma, developed by Plasmatreat GmbH in Steinhagen, North Rhine-Westphalia, fills this gap by expanding the range of products available with the new solution.

Magnus Buske, managing director at Plasmatreat GmbH, said: "With HydroPlasma, we offer the industry a powerful, eco-friendly, and cost-effective solution to one of the greatest challenges of modern manufacturing — the reliable, chemical-free cleaning of a wide variety of surfaces. This opens up new avenues for quality and sustainability in production.

“But our technology is not only suitable for cleaning; it can also be used for coatings. Our PlasmaPlus AntiCorr application is specifically designed for metal applications, such as housing seals in the automotive industry. In this case, we apply an ultra-thin, silicon-like layer that reliably and sustainably protects components from crevice corrosion. This process is already in widespread use and meets the usual climate and salt spray tests, such as PV1209 or the MeKo-S test.’