Suitable for production shops where manual mills may still be in operation, but equally well-suited to use on a vertical machining centre (VMC), a manually adjustable indexing head has been introduced by Salisbury-based 1st

Machine Tool Accessories (

www.1mta.com).

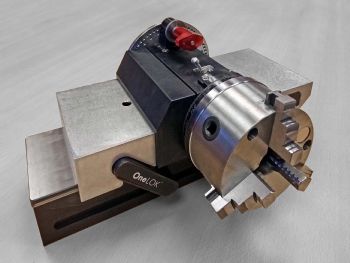

The RotaVice can be rapidly set to position a component at a large variety of rotary angles in the horizontal plane for milling and drilling.

Produced in the UK, it is designed to be secured in a One-Lok work-holding device made by Chick in the USA, for which 1st MTA is the sole agent in the UK and Ireland.

Costly fixtures and the need to change machine set-ups can be avoided, saving money and time.

In smaller job shops using four-axis VMCs equipped with a full or indexing rotary table, where there may be only one or two people able to program the machine, their load can be lightened by having a lower-skilled operator set up a component manually for three-axis machining.

Everything about the RotaVice is fast. A One-Lok is first bolted onto a VMC table.

Next, positioning the movable jaw using the built-in ratchet mechanism requires only a few turns

of the handle to clamp the indexing head in a special RotaVice jaw (also made by 1st MTA), which replaces the standard One-Lok jaw.

The workpiece is finally secured in a horizontal orientation, using an array of work-holding options, which include a three-jaw chuck.

Adjusting the angle is carried out by turning a circular locating plate to the required angle and inserting a pin into the relevant hole; an array of these are pre-drilled into the plate at the most common angles (in the standard

configuration, 5, 10 and 45deg are available).

The standard plate can be changed for a specific plate to suit any job that involves the use of non-standard angles.

Another advantage of the RotaVice is that once the angle has been selected, it uses the clamping force of the One-Lok to secure the rotary angle.

This force is much higher than that offered by standard dividing heads and allows significantly heavier machining cuts to be taken while maintaining a high level of surface finish.

Altering the angle for a subsequent machining operation on the same component is similarly achieved without having to re-clamp.

Intermediate angles can be set using a rotary dial with a 1deg increment scale, while very fine adjustments down to ± 0.5deg can be made using the toggle lever mounted at the top of the unit.

Importantly, RotaVice has a large through-bore with a taper and an internal thread, both of which can be configured for use with chucks, mandrels, special fixtures and back-stops.

1st MTA says these are normally not associated with standard dividing head systems.