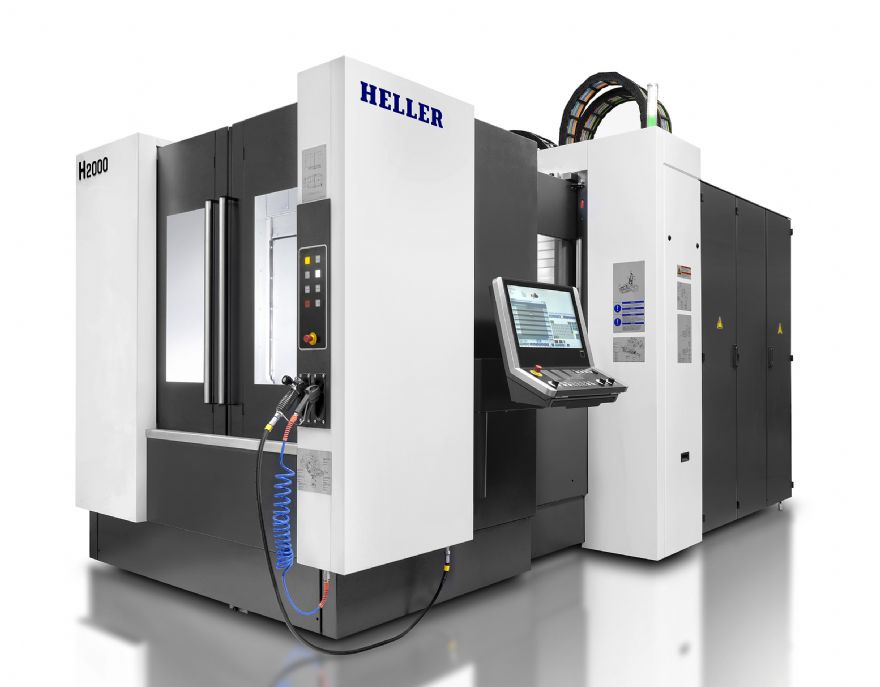

Under the banner of its 2021 slogan 'Be A Performer', Germany-based Heller has introduced a fourth generation of its H-Series four-axis, twin-pallet-change, horizontal-spindle machining centres.

The four smaller models, H2000, H4000, H5000 and H6000, which constitute half of the range, have been extensively upgraded in terms of both hardware and software to increase their productivity and improve their quality even further.

A website landing page has been created for this product launch - Heller - designed to guide visitors around the new features of the machines. It includes videos and a performance check area, where prospective customers can fill in their requirements and be directed to the most appropriate machine — all models are individually configurable.

The range is available in the UK and Ireland through the German firm's subsidiary in Redditch, where many of the machines are assembled

Heller Machnine Tools Ltd.

The complete makeover has seen the introduction of faster tool changes and optimised sequencing, nine new spindles, more structural stability to maximise metal cutting capability throughout the entire working volume, even at the extremes of axis travels, and a Heller graphical user interface for the Fanuc control option.

The new Gen4 models offer the same machining volumes as the previous versions - 630, 800, 800 and 1,000mm

3 respectively. The smallest model has a maximum table load of 800kg, while the larger machines support 1.4 tonnes on the table. The full H-series range extends through four more machines to the H16000 with axis travels of 2.4 x 1.6 x 1.6m.

Optimised tool changeWith reduction in production cost per part firmly in mind, an optional SPEED equipment package offers elevated rapids of up to 90 m/min, as well as optimised tool change at three speeds that are tool weight dependent and faster rotary clamping to deliver a reduction in chip-to-chip time of up to 21%.

The package also optimises Z-axis and B-axis dynamics according to the fixture mass and the weight of the component on the table. Additionally there is a POWER package with standard rapids up to 65m/min and tool change times that have been reduced by up to 15%, offering linear rather than rotary encoder feedback of axis position in X, Y and Z.

New is the availability of two DC (dynamic cutting) universal direct-drive motor spindles, HSK-A63, 16,000rev/min, 180 Nm; and the HSK-A100, 12,000rev/min, 400Nm, and a PC (power cutting) spindle, HSK-A100, 10,000rev/min, 360Nm.

There are also six new inline spindles, bringing the total number of options to nine, all featuring the 'Heller zero-spindle system' for rapid interchangeability, leading to maximum machine availability coupled with low service costs.

An out-facing slide system for internal boring and external turning is available, with control of the requisite U-axis already integrated into the machine control.

It is noteworthy that all of the manufacturer’s compact, high-torque spindles feature ease of servicing, integrated leakage checking to prevent damage and rapid run-up times for high productivity.

Higher rigidityThey are all produced in-house in a recently-opened, air-conditioned, automated facility at Heller's headquarters in Nürtingen. The rotary table, with a milling torque of up to 2,900Nm in the two larger machines, has been FEM-optimised and reinforced with a YRT-C bearing for higher rigidity as well as more rapid positioning and clamping.

Its improved robustness and symmetry of construction allows components to be machined at the extremes of the X and Y axis strokes, a goal further promoted in the two smaller Gen4 models by increasing the width of the linear guideways from 3 to 45mm.

Being able to use the whole working volume to maximum effect can have a big influence on finances, as it is possible to choose a smaller size of machine for a given set of intended applications and thereby reduce capital investment and running costs.

Electrolytically galvanised internal guard surfaces and liberal use of stainless steel in the machine construction, notably in the working area and the tool and workpiece setting stations, enhance durability while steep side walls promote efficient evacuation of swarf.

LED lighting has been improved in all operator areas and a camera can be integrated above the tool change door. Easy access to the working area, a short distance from the front of the machine to the spindle and a low component loading height ensure ergonomic machine operation.

Rapid mounting of fixturesFor tool storage, seven chain-type magazines with up to 240 pockets are available as well as three rack-type magazines with up to 425 positions. The standard lifting and swivelling pallet changer with hydraulic clamping exchanges pallets with standardised alignment elements for rapid mounting of fixtures.

An integrated, five-point media interface to activate hydraulic or pneumatic fixtures and feed data back to the control is optional throughout the range, while the two larger machines may be equipped with a seven-point media interface with 80-bar or 200-bar hydraulic pressure.

The control consoles where the operator interfaces with the machine, including at the component and tool setting areas, have been made even more user-friendly. The operating console of the Siemens Sinumeric 840D sl control has a 24in touch screen, while the Fanuc 31i-B 15in touch screen option has gained a Heller graphical user interface and a newly designed HMI panel.

Heller4Industry functions are very much in evidence for enhancing production efficiency and for machine monitoring. The optional software suite is universally applicable from a single machine with or without a network connection, through multi-machine sites, to multi-site operations with cloud-base communication.

The standard umati interface (universal machine technology interface) enables machine and production data acquisition. Monitoring of potential collisions, energy consumption, axis wear, spindle condition and tool overload and breakage are all application options.