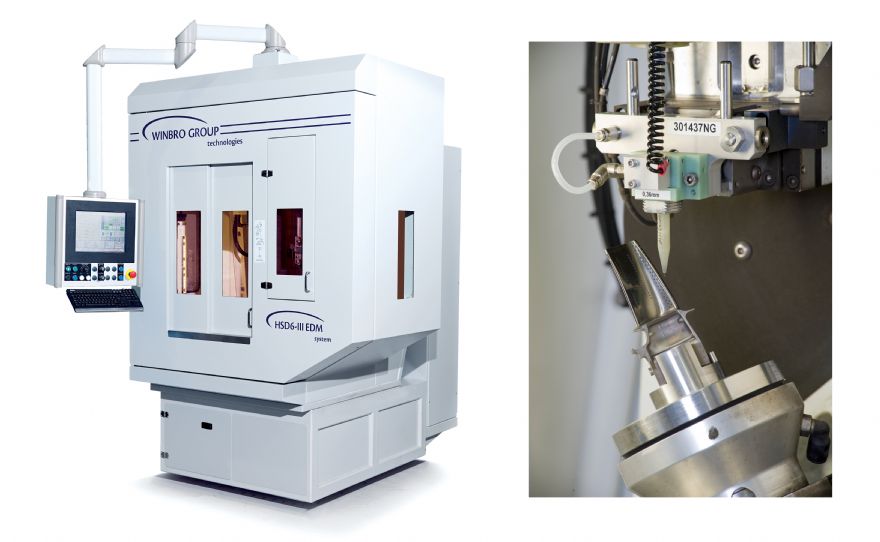

Aerospace parts precisely machined on the Winbro HSD6-III high-speed EDM drilling system

Aerospace parts precisely machined on the Winbro HSD6-III high-speed EDM drilling systemThe Wellesbourne-based

Engineering Technology Group (ETG) has now added the Winbro HSD6-III high-speed EDM drilling system to its portfolio.

Designed and manufactured in the UK by the

Winbro Technologies Group, the system offers industry-leading performance while maintaining stringent metallurgical requirements that are commonplace in the aerospace and IGT markets.

The Winbro HSD6-III has been specially developed for the machining of cooling holes, forms and features in turbine blades, nozzle guide vanes (see picture below), seal segments and other components that require high-speed EDM drilling.

Capable of production rates up to five-times faster than conventional EDM machines, the Winbro HSD6-III is ideal for processing round holes from 0.3 to 3mm diameter with a maximum depth up to 100mm. The machine is also capable of complex 2-D and 3-D diffuser holes with its advanced shaped hole generation technology.

Precision is assured with Winbro’s advanced and patented six-point probing system that guarantees accurate positioning of drilled holes — this technology enables the use of simple and easy-to-use fixturing technology for positioning components and adapting to casting variation.

The Winbro HSD6-III also offers the option of on-machine inspection to guarantee true hole position via a laser opticator measurement system. This high level of precision is complemented by the signature analysis feature that monitors the drilling performance in real-time to reduce the requirement for manual inspection processes while compensating for casting core movement.

The precision level of the Winbro HSD6-III is its stand-out feature with a linear accuracy and repeatability of 0.010mm and 0.008mm respectively with a rotary accuracy and repeatability of 20 arc/sec and +/-15 arc/sec.

Furthermore, the work envelope of the Winbro HSD6-III offers X, Y and Z axis travels of 200 x 200 x 250mm that can accommodate workpieces up to 225 x 225 x 225mm. For larger workpieces, ETG can present a number of alternative technology solutions from Winbro to suit most component types and sizes.

The flexibility of the Winbro HSD6-III is demonstrated by the rotary A-axis of +/-185deg, B-axis of 135deg +100deg and a rotary C-axis of +/-8deg that enables the component to be interpolated for complete 5-sided part processing in a single set-up.

The tooling configuration of the Winbro HSD6-III is also flexible to suit the demands of the end-user with the choice of single-point rotational or static electrode for non-line-of-sight, while high-productivity environments can opt for the multi-tool option with up to 45 sensed electrodes.

The tool station is supplied via a single automated electrode changer with a 12 electrode automatic change station to meet the needs of automated or prolonged production cycles.