Coventry-based

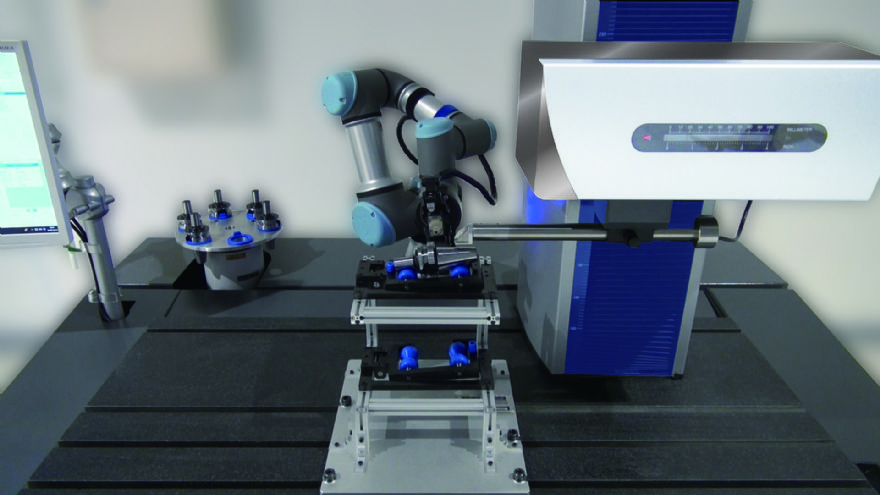

Accretech UK Ltd recently launched the Surfcom NEX, the latest evolution of the popular Surfcom range allows both surface and contour measurements to be made flexibly and accurately by a single machine. Furthermore, the highly efficient instrument delivers measurements up to 60% faster.

In addition to use within cleanrooms, due its ability to function across a range of temperatures, the robust machine can also be used within production environments. Surfcom NEX innovations include the use of a hybrid detector for simultaneous contour and surface measurement, an electromagnetic drive allowing the detector to move without wear and tear or vibration, and a linear drive system, ensuring quick, low-oscillation measurements with no disruptive noises or vibrations.

Marcus Czabon, head of the metrology business unit at Accretech, said: “The new Surfcom NEX is the result of many years of intense dialogue with our customers. It offers quality controllers and production managers versatility, precision and, most importantly, reliability. In terms of equipment and features, it sets a benchmark in contour and surface measurement; not least when considering procurement and operating costs over the product lifecycle.

“We want to accommodate the changing demands in production and tool inspection. In simple terms, more parts need to be checked in a shorter time. So, diverse application options are a driving factor. Our customers want to use just one machine for surface texture and contours. It must be possible, therefore, to combine detectors freely or to carry out hybrid measurements.”

Mr Czabon added: “However, reliability should not in any way be compromised by faster and more complex measurement processes. That is why the Surfcom NEX has a newly developed hybrid detector, which has over twice the coverage of traditional machines.”

In fact, the surface texture and contours (radii, angles or clearances) are evaluated in a single track. If desired, additional detectors can be used for roughness and contour measurements depending on the part. This means the Surfcom NEX is genuinely versatile and can do the job of two measurement devices.