Now available from the

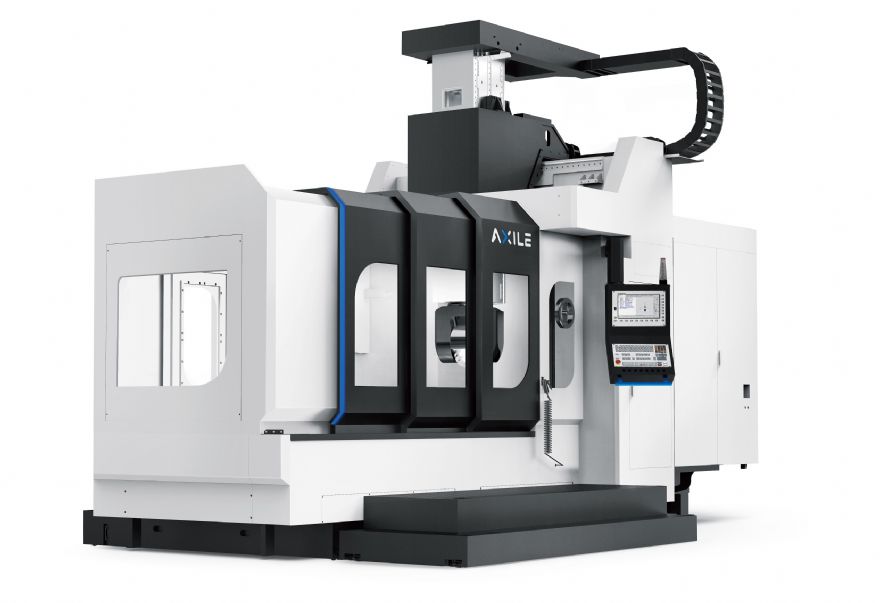

Engineering Technology Group (ETG), Wellesbourne, is the new DC12, a double-column five-axis vertical machining centre from the Taiwanese manufacturer Axile.

Designed for processing large parts typically found in the aerospace, power generation, and mould and die industries, this machine accommodates a maximum table load of 2.5 tonnes and a maximum component length of 2.2m; a workpiece diameter of 1.3m can be accepted by the built-in 1.2m-diameter rotary table, while the double-column bridge construction provides high levels of rigidity and control over thermal deformation — capabilities that allow the machine to undertake both heavy-duty cutting and precise complex contouring.

To ensure effective chip removal, the DC12 has a chip auger, chip conveyor, through-spindle coolant, four coolant outlets at the spindle nose, air flushing, and a chip wash down facility; and despite its size, the DC12 incorporates directly driven servomotors, roller-type linear guideways, pre-loaded double-nut ballscrews, and linear scales (0.1µm resolution) on the X, Y and Z axes. Also featured are an HSK-A63 swivelling head B-axis and a rotary C-axis that is integral with machine bed. The spindle can be supplied with up to 90 or 120 HSK-A63 tools or 60 HSK-A100 tools.

The DC12 has a work envelope of 2.2 x 1.4 x 1m, 36m/min maximum feed rate, ±110deg swivel on the B axis, and a 360deg rotary C axis — both with a maximum speed of 100rev/min. Fitted as standard is an HSK-A63 45kW 20,000rev/min spindle; an HSK-A100 high-torque (241Nm) 16,000rev/min spindle is an option. Axile also offers the DC12 MT, which combines both milling and turning, with the rotary table offering rotational speeds up to 800rev/min; there is also an HSK-T interface for the spindle.

Regarding options, the DC12 can be specified with either a Heidenhain, Fanuc, or Siemens CNC, automatic workpiece measurement, tool measurement embedded in the table, air conditioning units, and 40 or 70bar coolant pumps. A motorised pallet changer can also be specified.