Sandvik Coromant

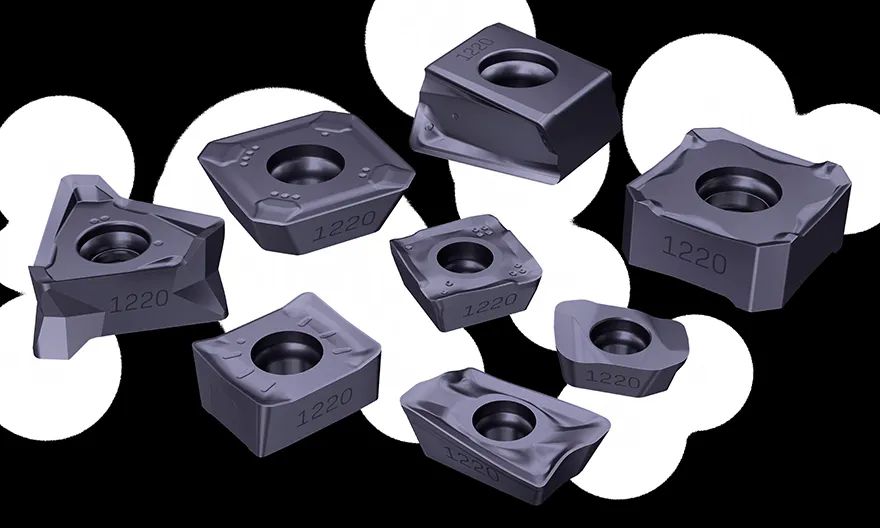

Sandvik Coromant has introduced its latest innovation in indexable milling with the launch of

GC1220, a new grade especially developed for nodular cast iron. Designed to deliver exceptional performance, reliability and efficiency, GC1220 represents a major step forward in cast iron machining technology.

At the core of GC1220 is a breakthrough in coating technology. The grade features a nano-multilayer PVD coating created using Sandvik Coromant’s renowned Zertivo process. This advanced coating combines titanium aluminium nitride (TiAlN) and titanium silicon nitride (TiSiN), offering a rare synergy of edge line toughness and wear resistance — a combination traditionally seen as a trade-off in conventional grades.

Wayne Mason, global product application manager for grades at Sandvik Coromant, said: “GC1220’s ground-breaking coating innovation delivers exceptional performance with security, predictability and sustainability. It is the first choice for all nodular cast iron milling applications at light roughing to finishing applications in wet and dry conditions.”

Most demanding machining environmentsThe new grade is engineered to withstand the most demanding machining environments, whether in wet or dry conditions. It offers outstanding resistance to abrasive wear and thermal cracking, ensuring stable and secure performance even under challenging conditions. Building on the success of the GC1230 steel milling grade, GC1220 continues Sandvik Coromant’s tradition of innovation in PVD coating technology.

Mr Mason continued: “This new cast iron milling grade builds on the same proven innovation as our successful GC1230 steel milling grade. With its advanced Physical Vapour Deposition (PVD) coating and robust performance in demanding conditions, GC1220 will define a new level of performance for cast iron machining.”

GC1220 inserts are designed to deliver longer and more predictable tool life, helping manufacturers reduce downtime and boost productivity. This reliability also contributes to more sustainable production processes, aligning with industry goals for both performance and environmental responsibility.

Optimised for light roughing to finishing operations, GC1220 is suitable for a wide range of applications — from general machining to more complex tasks such as square shoulder milling, interrupted cuts, skin conditions and intricate tool paths. It is the preferred choice for nodular cast iron (K3), and also performs well on malleable and grey cast irons (K1/K2), across all industry segments.