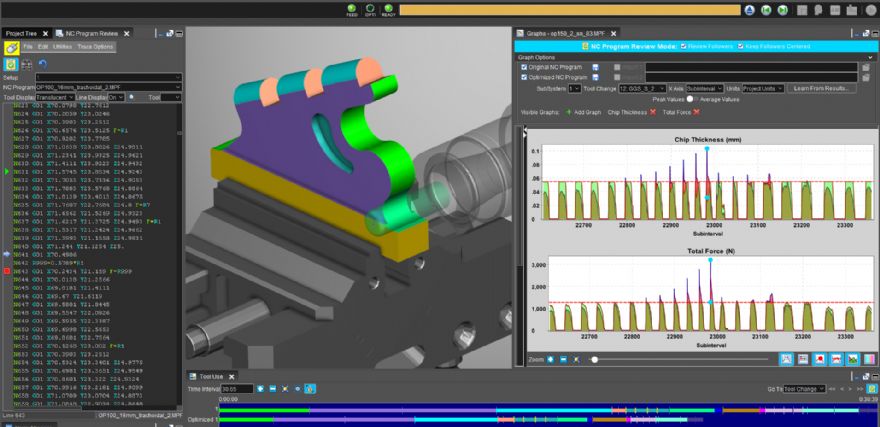

Pictured right: the Grob 550T used in the energy monitoring project and machining process Vericut

Pictured right: the Grob 550T used in the energy monitoring project and machining process Vericut Optimizer, the stand-alone version of Vericut’s integrated Force module, has long been recognised for its ability to reduce cycle times in CNC machining. However, substantiating its impact on energy consumption has proved more elusive — until now. A recent independent trial involving

Seco Tools,

Virtual Manufacturing UK and

Grob has confirmed that the software’s predicted energy savings are not only theoretical but measurable in real-world conditions.

The trial centred on machining a titanium (Ti-6Al-4V) sample workpiece featuring complex freeform surfaces, pockets and slots. Initially, the unoptimised cycle time stood at 30min and 35sec. After applying Vericut Optimizer, this was reduced to 23min and 6sec — a 24.5% improvement. The operations included dynamic milling, face milling and radius cutting, using a range of Seco cutters such as solid-carbide end mills and indexable-insert shoulder mills.

To verify energy savings, Virtual Manufacturing UK fitted current clamps and a sender unit to the three-phase, 440-volt main feed of the Grob 550T universal CNC mill-turn centre. The system monitored energy consumption in real time for both the optimised and non-optimised NC code. Henrik Nyby, manufacturing consultant at Virtual Manufacturing UK, explained: “For the purposes of trial expediency, data analysis took place manually using spreadsheets. Virtual Manufacturing UK specialises in real-time energy monitoring and digital optimisation tools for manufacturers, with Gazpacho Energy at the heart of our offering.”

Hard evidenceThe results were striking. The Grob machine consumed 13.75kWh during the unoptimised cycle, compared to just 11.11kWh with the optimised code — a 19.2% reduction. This closely matched Vericut’s algorithm-based prediction of 19% energy savings. Scott Ravenscroft, sales manager at Vericut UK, said: “Having won the award, we wanted to back-up calculated savings with hard evidence of the energy savings that Optimizer provides. We asked Seco Tools to produce a sample component on its Grob 550T universal CNC mill-turn centre and invited Virtual Manufacturing UK to monitor the machine’s energy consumption in real time.”

The trial also highlighted how certain machining strategies, such as adaptive milling, delivered higher energy savings than others. Luke Manders, development engineer at Seco Tools UK, noted: “Interestingly, certain machining strategies, such as adaptive milling, appeared to deliver higher energy savings than other operations. The trial proved useful in many ways, helping to grow our knowledge of this technology.”

Pictured left: 3-phase current clamps from Pressac Communications installed on the CNC machine’s incoming mains

Pictured left: 3-phase current clamps from Pressac Communications installed on the CNC machine’s incoming mainsAlthough the trial did not run long enough to verify the extended tool life of up to 30% that Vericut has observed in other customer applications, the potential remains significant. Optimizer balances high cutter engagement for productivity with the need to prevent excessive force, deflection and chatter — factors that can shorten tool life.

The collaboration between Vericut, Seco Tools, Virtual Manufacturing UK and Grob was recently recognised with the ‘2025 Sandvik Sustainability Award in Memory of Sigrid Göransson’. David Magnall, innovation partnership manager at Seco Tools UK, said: “Our Innovation Hub at Alcester is where we assess factors beyond just cutting tools. We look at more holistic solutions for customers, perhaps involving digitalisation or sustainability, for example. All projects take place in collaboration with technical partners, in this case Vericut, Virtual Manufacturing UK and Grob.”

Looking ahead, Seco Tools UK plans to extend the sustainability theme at its ITI (Inspiration Through Innovation) event in February 2026. Mr Magnall revealed: “We are working towards the creation of an entire end-to-end sustainability demonstrator. By considering the manufacture of a component from start to finish, we plan to show how many process touch points we can impact in terms of sustainability. In total, the demonstrator will involve solutions from around 12 technology partners, with Vericut Optimizer playing a central role.”

As manufacturers increasingly factor sustainability into investment decisions, technologies like Vericut Optimizer offer a compelling proposition — not only in terms of productivity and efficiency, but also in reducing environmental impact. Mr Magnall concluded: “If we can offer sustainable, holistic solutions, the impact on the manufacturing industry will be positive and profound for all stakeholders: technology suppliers, users and funders.”