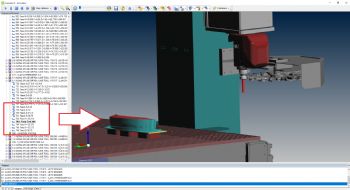

The latest release of AlphaCAM (2020.0) from Hexagon Manufacturing Intelligence’s Production Software business (

www.Hexagon MI.com), includes enhancements to the ‘Post processor’ engine, which delivers what is described as ‘best in class’ technology.

Brand manager Hector Henry said: “We can confidently back up that claim, as the enhancements mean the post-processor

engine directly configures and deploys a simulation session, resulting in more-realistic motion, as well as the ability to support cycles such as M6 — and additional hardware that has previously been under-utilised or ignored.”

The ‘Automation suite’ has been enhanced, improving productivity when creating and deploying job configurations; and new ‘Setup Wizards’ have been designed to make “short work of daily production tasks”.

With regardto solids machining — specifically, machining solid faces directly — Mr Henry says AlphaCAM sets a new standard by allowing direct interaction with them.

“Previously, we enhanced our solids interaction by allowing users to ‘saw’ a solid face directly.

The Rough/Finish command (profiling) now allows the user to directly select and machine a solid face; and if a machine supports tool compensation on custom orientations (planes), this option provides the ability to create precision parts with minimal effort via the use of G41/G42.”

Advanced five-axis functions now include the ability to integrate the ‘Tool-path Optimiser’ into a core cycle that can then be stored in a machining style and used with ‘Automation’; and the advanced five-axis capability has been updated to include barrel mills and double-profile tools.

Improvements in Swarf machining, multi-axis roughing and tool-path smoothing are also included.

Meanwhile, the ‘Geometry Offset’ command now delivers an intuitive and simple way of changing tool-paths, for everything from simple tasks such as passing associative/dynamic profile machining data to complex ones — including re-assigning a boundary to a 3-D surfacing method.