PTG Holroyd HG350-WG

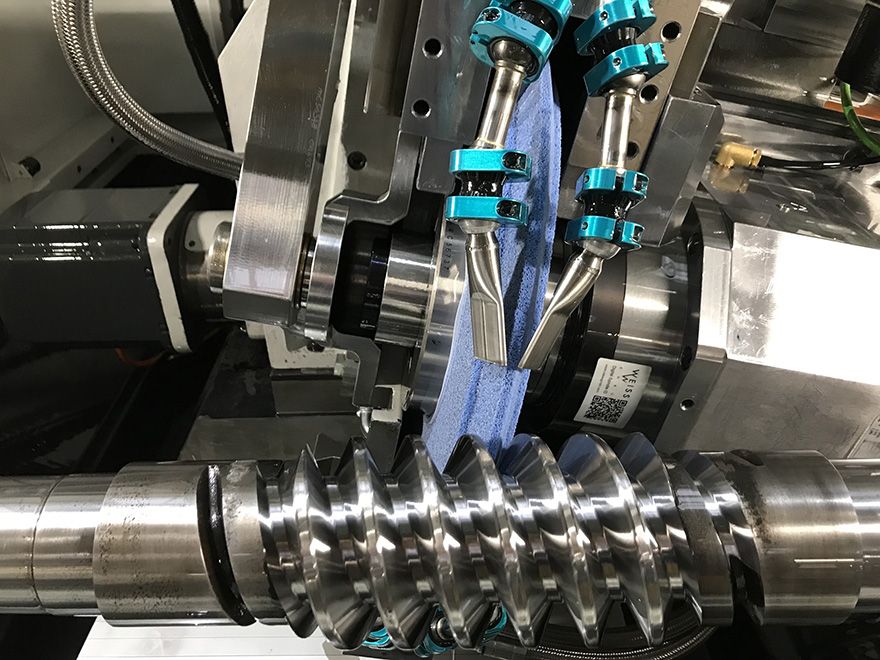

PTG Holroyd HG350-WGManufacturing high-accuracy worm gears and screws alongside precision spur and helical gears has traditionally required the use of two quite different CNC grinding machines. Thanks to Rochdale-based

PTG Holroyd’s newly launched HG350-WG worm and gear grinding centre, however, just one machine can now complete both tasks.

PTG Holroyd sales director Mark Curran said: “Since the launch of our HG350-G (gear-only) grinding centre in 2021, we have been investigating ways of bringing manufacturers of worms or gears, or both, greater levels of flexibility and efficiency in their manufacturing processes.

“The result of a multi-million-pound machine tool development programme, our new HG350-WG worm and gear grinding centre, does just that. Taking the concept behind the HG350 range a stage further, the dual-capability ‘WG’ model has been designed not only for the one-off and batch grinding of high-accuracy worms and screws, but also for precision grinding spur and helical gears of up to 350mm dia.

“Primarily, that means significantly improved versatility for manufacturers who need to quickly switch between grinding processes. Many other businesses will now only need to invest in one type of helical grinding machine tool while, for others, selecting a HG350-WG model will mean being able to expand their manufacturing capability to either worms or gears.”

Designed from the ground up to bring greater levels of efficiency and accuracy to the production of specialised gears and tooth forms, this latest member of the HG350 family features an advanced version of the company’s acclaimed HPMS (Holroyd profile management system) for rapid programming and seamless background calculations of both worms and gears. In fact, operators will only need to input the profile shape and size they wish to achieve for a precise dressing path to be created.

Just like all PTG Holroyd HG350-G gear grinding machines, the new HG350-WG worm and gear variant is controlled by

Siemens’ highly intuitive Sinumerik ONE future-proof CNC. PTG Holroyd was the first UK machine tool manufacturer to embrace the benefits of the Sinumerik ONE control, a decision which has helped to equip its HG350 range with class-leading integrated safety and failsafe features, enhanced reporting of machine health and performance data, and uncompromising levels of industrial security.

Mr Curran adds: “Using the Sinumerik ONE CNC has also allowed us to equip HG350-WG models with Siemens’ ‘Create my virtual machine’ and ‘Run my virtual machine’ software capabilities. When used in tandem with our own internal machine design packages, these features have enabled our teams to build virtual ‘digital twin’ HG350-WG worm and gear grinding centres on the desktop, then grind virtual gears and threads — all while observing entire manufacturing cycles, and testing safety and failsafe capabilities.

“The software also makes acceptance testing exceptionally straightforward, as our customers are able to sign off on their new machine before it has even been built. Then, following installation, they too can benefit from carrying out ‘virtual’ gear and worm grinding to ensure right-first-time results.”

Industry firstsMaintaining PTG Holroyd’s pedigree of delivering industry firsts, the new HG350-WG is believed to be the first machine of its kind to use

Renishaw’s Sprint 3-D scanning probe, alongside Siemens’ Sinumerik ONE CNC, for rapid precision scanning for infinitesimal profile corrections. Mr Curran continues: “We have worked in close association with Renishaw and Siemens to use orthogonal data from the grinding machine’s X, Z (linear) and C (turning axis) to create a virtual Y-axis for use by the Sprint probe.”

HG350-WG machines feature the high power required for deep grinding operations. A specially developed extended machine bed allows screws and worm shafts of up to one metre in length to be accommodated. Dedicated software compensates for helical twist, and full topological capability comes as standard.

Embracing the Sinumerik ONE CNC’s Profinet capabilities, IO-Link communication technology will be offered with all new HG350-WG machines — as will RFID scanning, an option that will be particularly suitable for machines destined for production cells, by helping ensure that virtually any component or tooling item that needs to be switched between manufacturing cycles, is correctly changed for each gear grinding operation.

Continuing the PTG Holroyd tradition of building machines that simplify even highly complex manufacturing processes, the HG350-WG combines extreme rigidity with high power for both CBN (cubic boron nitride) and conventional deep grinding operations. On-board features include automatic coordinate adjustment, in-cycle wheel dressing, integrated profile management and coordinate measurement. Grinding cycles are included for: spur gears; helical gears; crowned helical and spur gears with root or tip relief; worm gears of the form ZK, ZI, ZN and ZA; dual lead (duplex) worm gears; and splines.

Incorporating the brands of PTG Holroyd, PTG Powerstir Friction Stir Welding and Holroyd Precision Rotors, PTG has established itself at the forefront of high-precision machine tool design, build and supply for specialised applications. The range includes advanced machine tools for the production of complex helical components such as compressor rotors, pump screws and high-accuracy gears, and Powerstir machine tools for friction stir welding advanced alloys used in transport applications.

With production facilities in the UK, USA and China,

Holroyd Precision Rotors manufactures the special purpose, ultra-precision helical components used in a wide range of industries, including refrigeration, air-conditioning, gas and vacuum pumping, industrial air handling, aerospace, medical equipment, motion control, power transmission, power generation, oil and gas, fluid transfer and high-end automotive. PTG also provides advanced technical consulting services.