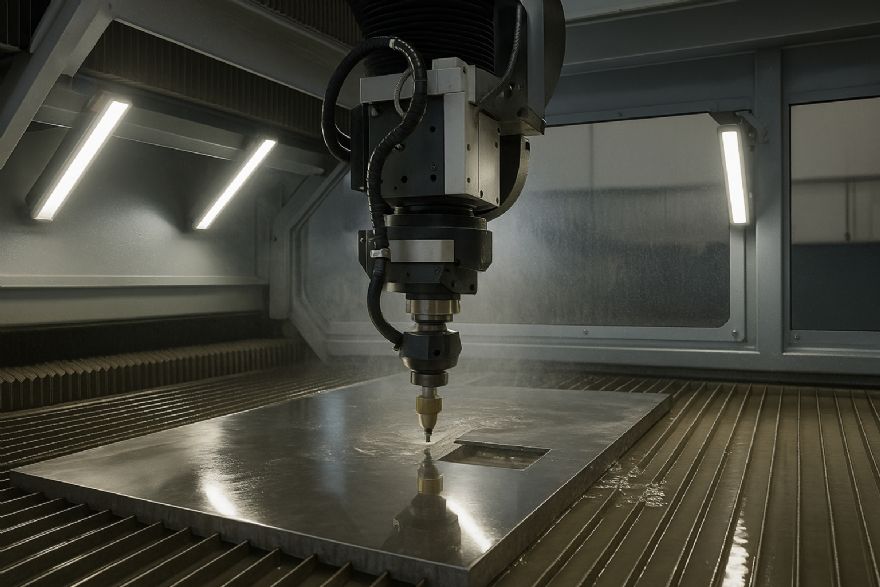

Waterjet cutting offers a cold process that sidesteps the thermal distortion common in traditional methods, delivering tight tolerances and clean finishes. By eliminating heat affected zones, it preserves the integrity of metallurgy, laminates, and coatings, making it especially valuable for reflective metals, composites, and brittle substrates like stone or glass. The key to unlocking consistent performance lies in how visibility and motion are managed within the cutting cell.

A waterjet cutting cell integrates a high-pressure pump, cutting head and nozzle, abrasive feed system, multi-axis motion platform, and a catcher tank with filtration. When these components are tuned correctly, the same cell not only cuts faster but also produces a cleaner finish.

The process begins with a CAD nest, which is converted into toolpaths. The controller executes these paths while the pump maintains pressure and the head regulates abrasive flow and stand-off. From nesting and pierce strategy to pressurisation and nozzle alignment, each stage contributes to the final cut quality. The controllables — pressure, flow, abrasive mesh and feed rate, stand-off distance, traverse speed, acceleration, and pierce dwell — determine whether downstream deburring is necessary or not.

Performance hinges on the mechanical and control systems that shape finish, tolerance, and uptime. Pumps, whether intensifier or direct drive, set the energy in the jet. Heads may run on pure water or abrasive, and motion platforms vary from gantry and cantilever to robotic arms. Filtration in the tank stabilises flow and visibility.

Techni Waterjet offers application notes that align closely with these principles, providing deeper insight into pump selection, garnet handling, and fixturing. Lighting plays a critical role in exposing mist, splash, and misalignment at the jet.

Proper illumination allows operators to catch issues before they result in scrap. A high-pressure pump elevates water to cutting pressure and feeds the head at a stable flow. Intensifiers excel at very high pressures using hydraulics, while direct drive pumps offer efficiency at moderate pressures through crank-driven plungers. Pressure stability directly correlates with edge stability. The abrasive feed system delivers garnet at controlled rates to the mixing chamber, balancing speed with finish. Overfeeding wastes media, while underfeeding causes striated edges. Mesh must be matched to material and thickness, feed rates set per recipe, and humidity controlled to prevent clumping — clean abrasive ensures predictable kerf.

Motion systems position the head along programmed paths using servo drives, encoders, and interpolation. Closed-loop control with look-ahead and jerk-limited profiles prevents force spikes and keeps the jet orthogonal through thickness.

ADVANCED Motion Controls provides practical guidance for drive sizing and feedback choices under splash and vibration.

Durability in wet environmentsTask lighting, when properly specified and placed, reveals edges, pierce points, and jet lag lines through mist. It shortens setup times, reduces re-pierces, and lowers operator fatigue. Fixtures should deliver 500 to 1,000 lux at the workplane, with CRI 90 or higher, and beam angles that cross-light the cut zone. IP67 or better ratings ensure durability in wet environments.

Lighting improves edge quality by making kerf wander, taper bands, and partial pierces visible before they become defects. It also enhances safety by reducing slips and making emergency stops more visible. Camera clarity for remote monitoring and in-process inspection also benefits from proper lighting. Critical lighting zones include the nozzle and stand-off area, pierce start point, camera viewpoints, tank interior, and part unload area.

The right lighting specification is practical and consistent: 500 to 1,000 lux, 4,000 to 5,000 K colour temperature, CRI 90+, low glare placement, and IP67 housings with chemical-resistant lenses. Fixtures should mount on anti-vibration brackets, angle off-axis to avoid back glare, and route cables in sealed conduit. Dimming or zone control helps cameras adjust exposure without blooming.

Dynamo LED Displays offers useful design notes for glare control and enclosure lighting.

LED task lighting outperforms fluorescent and halogen in efficacy, color stability, ingress protection, vibration resistance, and maintenance cost. LEDs run cooler, seal better, and dim cleanly for camera work. Fluorescents struggle with vibration and moisture, while halogen adds heat and can degrade seals and lenses. LEDs, with their long life and IP options, are the default choice in wet cutting environments.

Motion control in waterjet cutting is the silent partner in finish quality and cycle time. It governs how the jet behaves through corners and across varying thicknesses, and when tuned correctly, it transforms the controller into a finish tool. High-resolution servos with strong torque at speed, feed-forward control, look-ahead contouring, and jerk-limited S curves allow faster cutting without over-cutting tight radii. Corner deceleration prevents scalloping, stand-off compensation reduces taper, pierce ramp and dwell stabilise starts, and bead-on-edge compensation protects composites. These rules, when encoded into recipes, make finish repeatable and measurable by material and thickness.

Servos outperform steppers in waterjet gantries by delivering closed-loop accuracy, smoother profiles, fault reporting, and higher torque at speed. Their reliability in wet environments, when properly sealed, and their dynamic stiffness make them ideal for sharp corners and high feed rates. Steppers, while viable on small tables, struggle under high acceleration and feed demands. When finish is contractual and repeatability is audited, servos are the clear choice. Matching torque-speed curves to table inertia and jerk limits ensures optimal performance.

New level of precisionClosed-loop control with vision or probe feedback introduces a new level of precision. It corrects path deviations in real time, stabilises taper across thickness changes, compensates for nozzle wear before quality drifts, accelerates on straights while protecting corner geometry, reduces scrap on composites by catching delamination early, and enables automated in-process inspection for traceable records. These capabilities elevate both quality and accountability.

However, aggressive acceleration and jerk settings come with trade-offs. They can induce vibration striations on tall parts, cause overshoot at tight radii and thin webs, elevate stand-off errors on flexible bridges or worn ways, stress mechanical joints and shorten bearing life, amplify acoustic noise that masks leaks or alarms, and reduce camera readability due to motion blur and spray. Balancing speed with stability is essential.

Retrofitting a waterjet cell with sealed LED task lighting follows a clear sequence. It begins with a site lux audit and glare mapping, followed by fixture specification for IP rating, CRI, CCT, and beam angle. Lighting zones and switching are planned to separate pierce, cut, and unload areas. Wiring and conduit routes are designed to avoid hose sweeps and splash. Fixtures are mounted with anti-vibration brackets and aimed to cross-light the jet. Validation includes lux and shadow checks using test coupons and camera exposure tests. Operator training covers cleaning, inspection, and brightness control. Acceptance criteria confirm measured lux at the nozzle, no camera bloom or back glare, and stable visibility during pierce spray. Fixture IDs and locations are documented for maintenance.

Motion profile tuning is a recipe-driven process using coupons and KPIs. It starts with baseline acceleration and jerk settings by material and thickness, followed by calibration of stand-off and taper compensation. Look-ahead is enabled and corner rounding thresholds are set for minimum feature size. Pierce ramp and dwell are validated to prevent blowout. Feed and abrasive rates are swept to find the fastest clean edge. Golden recipes are locked in controller libraries with version control, and changes are documented with short work instructions for shift handover. KPIs such as edge Ra, taper angle, corner radius error, and parts per shift are tracked before and after. If numbers improve and remain stable, the settings are ready for production.

Lighting and motion upgrades pay back fastest in defect-sensitive or visibility-limited applications. Thin stainless with tight internal corners benefits from accurate deceleration and bright cross-lighting. Glass and stone require glare-free visibility to catch chips. Carbon fibre panels need adaptive feeds and good edge view to prevent delamination. Intricate gasket nests rely on vision to verify pierces and tab integrity. Quick wins are common in medical device brackets, aerospace shims, architectural glass, stone inlays, carbon fibre panels, rubber gaskets, and PCB laminates.

Scrap reduction and shorter cycle timesTypical costs for sealed LED task lighting packages range from $800 to $3,000 or euros per cell, depending on zones and optics. Controller firmware or feature unlocks fall between 500 and 3,000. Servo drive or encoder upgrades cost 2,000 to 8,000 per axis. Engineering time for design, mounting, and commissioning runs 1,000 to 5,000. Seven cost factors shape totals: enclosure IP rating, chemical exposure, camera integration needs, number of zones and fixtures, controller compatibility, labour for conduit and mounts, and commissioning or operator training. Scrap reduction and shorter cycle time usually drive simple payback in months, not years.

Safety and ergonomics are critical in wet, high-energy environments. Lighting prevents slips and trips, clarifies emergency stop locations, and makes tank maintenance safer. Motion risks are mitigated with guarded zones, safe speeds, and interlocks tied to door or curtain sensors. IP-rated fixtures and cabling, glare-free emergency stop visibility, lockout-tagout procedures for pump and motion, anti-slip platforms, eyewash and PPE placement, and inspection logs tied to preventive maintenance all contribute to safer cells and steadier output.

A clean finish is defined by low edge roughness, minimal taper, and crisp corners without delamination or chipping. Measurements include edge Ra in micrometers, taper in degrees or millimeters across thickness, kerf width consistency, burr-free edges on metals and composites, and chip-free glass or stone. Testing uses stepped thickness coupons, tight radius corners, piercing grids, long straightness runs, and composite edge peel tests. Lighting levels and motion recipes are logged alongside inspection results to ensure traceability.

Waterjet stands apart from laser, plasma, and mechanical routing by offering no heat affected zone and broad material reach. It excels in finish quality on thick or reflective materials. Fiber laser is ideal for thin metals at high speed but introduces HAZ and struggles with reflective alloys. Plasma is cost-effective for thick steel but rougher on finish. Mechanical routing suits composites and plastics but wears tools and generates dust. A hybrid cell combining waterjet with light deburring or micro-abrasive blasting can be optimal for aerospace brackets. The right process balances tolerance, edge integrity, and cost per metre.

Cold cutting reaches its full potential when task lighting reveals detail and motion control preserves edge integrity. The path to cleaner finishes and shorter cycles begins with small, measurable upgrades that show clear value to operators and engineers alike.

A disciplined pilot proves the gain and builds momentum. To get started, run a 10-point checklist in any cell. Begin with a baseline lux audit and set targets for CRI and CCT. Confirm IP ratings, angle and aim fixtures, and verify camera compatibility. Tune acceleration and jerk by thickness, enable look-ahead and corner rounding, and build coupon recipes that lock in performance. Log KPIs and acceptance criteria, then schedule quarterly revalidation of both lighting and motion settings. These focused actions compound over time into sharper corners, smoother edges, and more confident shifts.